In the realm of veterinary practices, packaging plays a pivotal role in preserving the integrity of medications, vaccines, and essential consumables such as sterile dressings. Beyond its functional necessity, outer packaging such as that received with wholesale deliveries, also plays a vital role in ensuring safe and secure shipping and storage. However, the environmental toll of traditional packaging cannot be ignored. In this article, we will take a closer look at sustainable packaging, exploring its various forms and the small changes that veterinary practices can adopt to reduce their overall environmental footprint.

The environmental impact of traditional packaging

As we all know, traditional packaging, often designed with convenience and cost in mind, has a significant negative impact on the environment.

The production of packaging materials, such as plastic, requires the extraction of finite resources and contributes to greenhouse gas emissions. Additionally, the disposal of single-use packaging leads to overflowing landfills and the pollution of natural ecosystems.

The impact of this can be best understood through statistics that highlight the scale of the problem and the potential for change.

According to the Ellen MacArthur Foundation, the equivalent of one rubbish lorry of plastic waste enters the ocean every minute, which amounts to 8 million metric tons of plastic every year. Without action, a report by Pew, suggests this could nearly triple by 2040.

And of course, it’s not just a matter of pollution and overflowing landfills, it’s also the huge amount of carbon emissions that are generated in the production and disposal of plastic. Experts from The Centre for International Environmental Law (CIEL) have estimated that…

“By 2050, the production and disposal of plastic could generate 56 gigatons of emissions, as much as 14% of the earth’s entire remaining carbon budget”

So, what is sustainable packaging?

Sustainable packaging aims to lessen its environmental impact while still fulfilling its necessary function. It goes beyond just being eco-friendly; it encompasses a range of practices that prioritise the use of renewable resources, minimise energy consumption, and generally reduce the carbon footprint.

Sustainable packaging materials

For most of us, the commonly recognised form of sustainability in packaging is that it uses recycled, recyclable or reusable materials. Each of these offers different solutions to achieve sustainability goals but combined, they contribute to the circular economy, the reduction in the amount of waste sent to landfills and the need for virgin materials.

Recyclable and recycled materials – keeping the circular economy turning

A great example of this is post-consumer recycled (PCR) plastics. PCR plastics are made from recyclable plastic waste that has been used and discarded by consumers. This waste is collected, sorted, and then processed to remove any impurities. The resulting plastic is then melted down and moulded to create new packaging products, which can then, in turn, be recycled once it’s served its purpose, keeping that original material in the economy for much longer.

The two most common types of PCR plastic that you would come across as a general consumer and as part of your work in practice:

RPET, Recycled PET (Polyethylene Terephthalate) – transparent, durable and lightweight, this is generally used in food and drink packaging.

RHDPE, Recycled HDPE (High-Density Polyethylene) – durable and lightweight, this is generally used in the packaging for pharmaceutical, nutraceutical, chemical and cleaning products.

Plant-based materials – using renewable resources

Plant-based packaging materials or bioplastics, are derived from renewable resources, such as plants or agricultural waste. These materials, a common type of which is PLA (polylactic acid) are made from biomass such as corn or sugarcane. They offer a more sustainable alternative to conventional plastics derived from fossil fuels and are biodegradable.

Biodegradable materials – navigating the healthcare complexities

Biodegradable and compostable materials have become a popular choice for packaging, however, it’s crucial to acknowledge the complexities surrounding biodegradability in the healthcare/veterinary sector. With contamination a concern, products labelled as biodegradable (or compostable) may end up having to be incinerated. Moreover, specific conditions are often required for optimal and timely biodegradation and some products may necessitate additives that aren’t environmentally sound.

Having said that, compostable packaging can be a good option in more general use, such as for single-use, food-based packaging, a great example of which is tea bags or coffee pods.

The complexity of biodegradable packaging in this context, highlights the importance of considering a holistic approach to sustainability, focusing on multiple attributes beyond biodegradability to ensure a genuinely eco-friendly impact.

Reusable materials – conserving resources and reducing single-use waste

Unlike traditional single-use packaging, reusable packaging is designed to be used multiple times before being recycled or disposed of. This approach encourages the return and reuse of the packaging and can take various forms; think of traditional glass milk bottles or the tote delivery boxes that your wholesale delivery arrives in. They’re typically made from more durable materials so that they can withstand multiple cycles of use.

Beyond materials: reducing, refining, and re-imagining

In addition to using sustainable materials, a multifaceted approach to packaging involves exploring various other options that can contribute to a more sustainable approach:

Concentrated and refillable products

Concentrated products are designed to be highly efficient and require less packaging material compared to traditional products. By reducing the volume of the product, less packaging is needed, resulting in less waste and a smaller carbon footprint from transportation and shipping.

These products seamlessly integrate with refillable containers, such as trigger spray bottles. Refillable products reduce the need for single-use items and reduce packaging waste, while also saving resources that would otherwise be used in manufacturing new containers. Where would you use concentrated and refillable products in veterinary practice? Generally, you would be looking at consumable products such as chemicals and those for cleaning/disinfection, maximising sustainability while maintaining efficacy.

Product Hero:

Select from NVS Ready to Use Disinfectant Cleaner Trigger Sprays that can be refilled from the 5L concentrate.

Re-designing/Reducing excess packaging

Reducing excess packaging is another crucial aspect of sustainable packaging. Many products are often over-packaged, with excessive layers of plastic or unnecessary materials. Re-designing packaging can help to minimise these excess materials and optimising packaging dimensions and weight can also help to reduce the carbon emissions created during transportation.

Product Hero:

Select from NVS Comfort Snap Collars – we’ve removed the unnecessary outer cardboard packaging.

Product Hero:

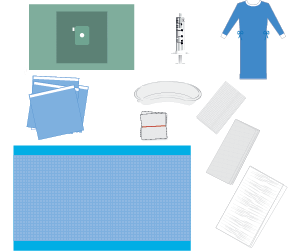

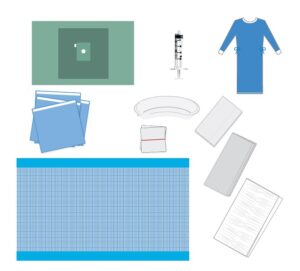

Select from NVS Small Animal Procedure Pack – using a procedural pack reduces the overall amount of packaging compared to single packaged items.

The pack contains: 1 x gown XL, 1 x hand towel, 1 x syringe (20ml luer slip), 1 x kidney dish, 1 x bundle of 5 x-ray gauze swabs 12 play, 4 x drape bi-laminate, adhesive edge, 1 x drape extremity, 1 x wrap crepe, 1 x supawrap, 1 x breather bag and 1 x trolley cover.

Water-based inks

Traditional printing inks often contain chemicals and solvents that can be harmful to the environment during production and disposal. Water-based inks, on the other hand, are made from water as the main solvent, reducing the use of volatile organic compounds (VOCs) and other harmful substances. Water-based inks are also easier to recycle and can be more easily removed during the recycling process, making them a more environmentally friendly choice.

Product Hero:

Select from NVS Sterilisation Pouches – printed using water-based inks.

Read more: 5 top tips to reduce the packaging footprint of your practice

The article was originally posted in The Cube magazine, February 2024 issue. Click here to read the magazine.